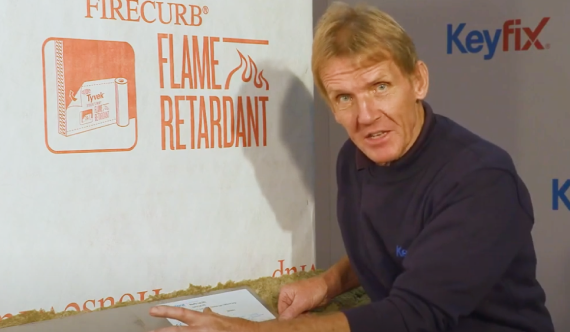

Non-combustible Cavity Tray Lintel

The Keyfix Non-combustible Cavity Tray Lintel (NCCTL) offers a non-combustible stainless steel single leaf lintel with combined Cavity Tray.

Make Enquiry

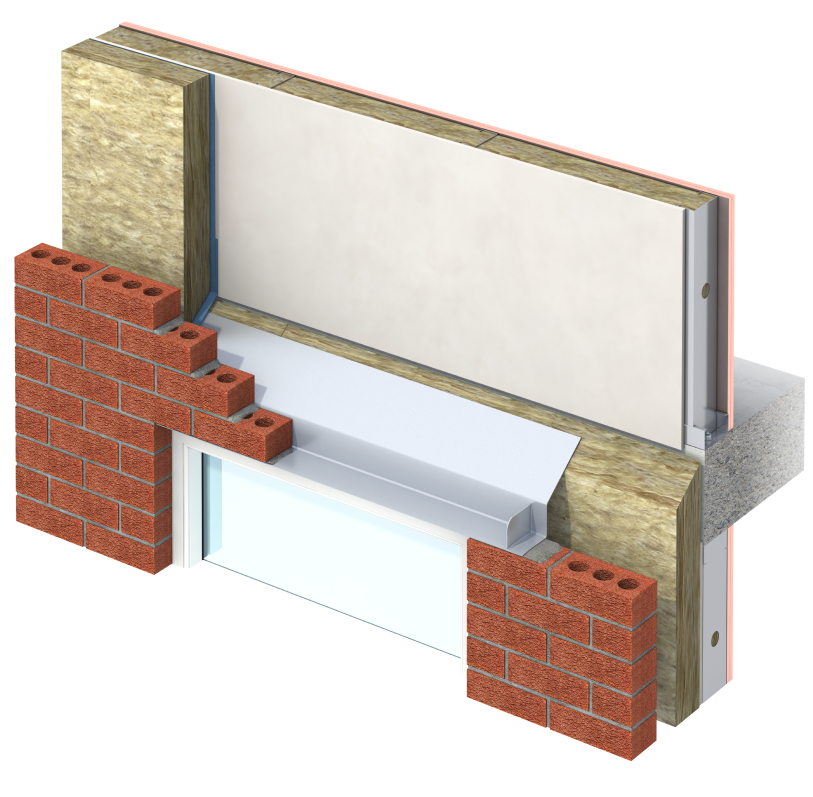

The NCCTL is for use in an exterior masonry skin in conjunction with a non-masonry inner leaf such as a steel frame system, the NCCTL is a highly efficient and practical solution to the challenge of non-combustible cavity detailing.

In buildings over 11m in height, Document B prevents the use of plastic DPCs, galvanised lintels cannot be used without a DPC, as the DPC protects the galvanised surface against attack from chemicals present within mortars etc. Stainless steel trays cannot be used with galvanised lintels due to galvanic corrosion caused by reactions between dissimilar materials.

1

2

3

4

5

6

1

2

3

4

5

6

We invite you to make contact with our technical design team to collaborate or enquire about a project.

Contact UsDiscover our latest CPD “Solving the non-combustible Challenge with Keyfix Cavity Tray systems”

Request CPDEnter your name and email address below to keep up to date with Keyfix product developments, CPDs, industry news and much more.