Non-combustible Cavity Tray System

Keyfix Non-combustible Cavity Tray is a Patented, BBA Certified, A1 fire rated system. Let’s futureproof the lifespan of your building together.

Make Enquiry

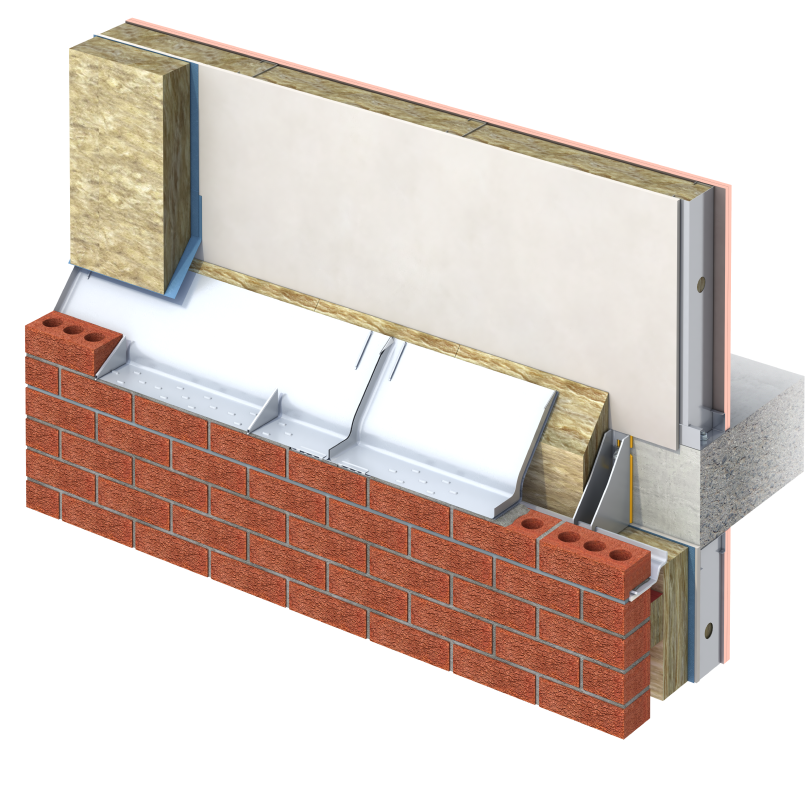

Keyfix is setting new standards in the delivery of Non-combustible Cavity Tray Systems for projects requiring Document B compliance in buildings utilising steel frame systems in the external cavity. Our innovative non-combustible A1 fire rated Cavity Tray system is a practical and technically superior solution to provide DPC protection over lintels, masonry supports, soffit systems and other elements in the cavity such as fire barriers.

1

2

3

4

5

6

1

2

3

4

5

6

Fully Accredited Solutions

Fully Accredited Solutions

The Keyfix Non-Combustible Cavity Tray System has been awarded a BBA Certificate and is the only non-combustible cavity tray system to not rely on tapes and mastics to make watertight joints, therefore eliminating one of the main reasons for product failure.

The system is approved by Premier Guarantee and LABC Warranty following their comprehensive review of innovative products and systems.

We invite you to make contact with our technical design team to collaborate or enquire about a project.

Contact UsDiscover our latest CPD “Solving the non-combustible Challenge with Keyfix Cavity Tray systems”

Request CPDEnter your name and email address below to keep up to date with Keyfix product developments, CPDs, industry news and much more.