Olive Morris House

South London

South London

South London

South London

South London

The Keyfix Non-Combustible Cavity Tray has been installed as part of a new residential development in South London, ensuring that the building is fully compliant with building regulations for years to come, as well as offering improved buildability.

Led by developer Notting Hill Genesis, design and build contractor McAleer & Rushe, architect Cartwright Pickard, and brickwork contractor Callan Construction, Olive Morris House is a new build residential development that forms part of the Brixton Hill regeneration project.

Replacing the former council offices, the regeneration project heralds the construction of a new seven storey building, overlooking Rush Common. This new structure will house a total of 74 residential homes, comprising 44 private residences, 30 of which are considered affordable, available in various configurations of one, two, and three bedroom units. The construction is now complete, with the ground floor and basement of the building housing the London Borough of Lambeth archive.

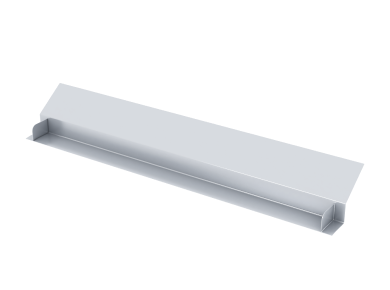

Working closely with McAleer & Rushe, Keyfix supplied 1,620m of its Non-Combustible Cavity Tray (NCCT), 75 no. of its Non-Combustible Cavity Tray Lintel (NCCTL), 966 pre-formed Corner Units, and 5,582 Keyfix Non-combustible Weep Vents to the project.

Olive Morris House required products that not only adhere to current regulations but also surpass them, with a focus on future-proofing the building. As a result, main contractor, McAleer & Rushe specified Keyfix’s NCCT for this project due to its rigorous compliance with regulations and its ability to protect the building against future regulations. The NCCT is crafted from A1-rated, austenitic Grade 304 stainless steel, providing a high standard of fire resistance for the building. Moreover, the enduring quality of austenitic stainless steel guarantees the product’s longevity, ensuring the building’s resilience for over 100 years. Subsequently, the building will remain in compliance with evolving regulations, even as they become more stringent.

On this project, Keyfix was able to accommodate a unique masonry design which featured dog-tooth panelling. To support the complex style of panelling, the base of the NCCT tray was altered to align with the leading edge of the brickwork, to produce a robust and cohesive brick façade.

Throughout the project’s duration, Keyfix consistently delivered outstanding levels of customer service to McAleer & Rushe. The project proceeded smoothly as the team actively engaged with the main contractor team and architects from the early stages of the design process. This proactive approach enabled the team to promptly and effectively address any issues that arose.

Keyfix offered extensive technical support to the stakeholders, which included active participation in design team meetings, regular follow-up calls to the site, conducting a Toolbox Talk, hosting a CPD webinar, conducting a thorough technical review of the architects’ drawings, and the provision of a comprehensive component schedule and location layout plan.

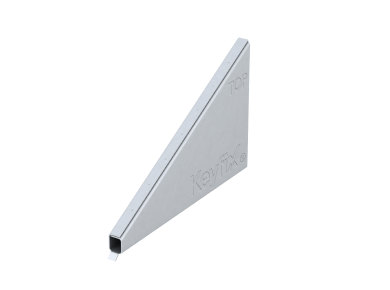

As a point of innovation on this project, the brickwork contractor utilised the Keyfix Non-Combustible Cavity Tray Lintel, as opposed to the traditional design which comprises a lintel with a cavity tray above it. The Keyfix NCCTL is a hybrid of both products and is manufactured as one complete unit, to help save on installation costs and enhance buildability. The Keyfix NCCT’s self-supporting ‘one-piece system’ enables a simple and efficient installation, as it doesn’t require fixing back to the internal frame, therefore saving valuable time when bricklaying.

Additionally, the Keyfix NCCT is notable for its unique design that eliminates the need for tape or mastics to create watertight joints. This innovation mitigates the most common cause of product failure, resulting in a more robust and dependable system.

Stephen McGinty, Project Manager at McAleer & Rushe commented, “Keyfix consistently delivered outstanding levels of customer service and their technical support was excellent, responding quickly to any issues we had. The onsite installation of the one-piece NCCT system they provided went smoothly and efficiently thanks to Keyfix’s expertise and the system was also able to accommodate the unique dog-tooth masonry detail which appeared on the project in localised areas. This self-supporting system not only meets but exceeds industry regulations for fire safety and thermal performance and I would have no hesitation in recommending Keyfix or utilising them again on other schemes.”

Commenting on the NCCT, Kieran Coyle of Keyfix stated, “The Keyfix Non-Combustible Cavity Tray was specified on this project due to its reputation for fire safety. The NCCT is an A1 fire rated system, providing our customers peace of mind as their building will always remain compliant with building regulations.”

The Olive Morris development has reached its completion, and the Keyfix Non-Combustible Cavity Tray has not only enhanced on-site efficiency but also secured the highest standard of long-term building safety for its occupants.

For more information about the Keyfix range of non-combustible solutions download the product guide, visit https://keyfix.com/or for technical support call 028 8676 7508 or email info@keyfix.com

Developer

Notting Hill Genesis

Main Contractor

McAleer & Rushe

Architect

Cartwright Pickard

Brickwork Contractor

Callan Construction

For more information about the Keyfix range download the Product Guide.

Download Keyfix Product Guide“Keyfix consistently delivered outstanding levels of customer service and their technical support was excellent, responding quickly to any issues we had. The onsite installation of the one-piece NCCT system they provided went smoothly and efficiently thanks to Keyfix's expertise and the system was also able to accommodate the unique dog-tooth masonry detail which appeared on the project in localised areas. This self-supporting system not only meets but exceeds industry regulations for fire safety and thermal performance and I would have no hesitation in recommending Keyfix or utilising them again on other schemes.”

Stephen McGinty, Project Manager at McAleer & Rushe

Related Projects

The Keyfix Non-Combustible Cavity Tray has been installed as part of a new-build project, Addiscombe Oaks in South London, helping to safeguard the development from fire and future building regulation changes.

Related Projects

The Keyfix Non-Combustible Cavity Tray System has played a vital role in the building of Ashley Road East, a major new residential development in Tottenham Hale, by improving installation efficiency and quality on site, and exceeding building regulations.

Related Projects

The Keyfix Non-Combustible Cavity Tray has been installed as part of a new residential development in the London Borough of Haringey, Ashley Road West. The innovative system has helped to improve efficiency onsite and to future-proof the building against fire safety regulations.

Related Projects

The Keyfix Non-Combustible Cavity Tray System has played an integral role in the construction of a new residential development in north London by exceeding building regulations and increasing installation efficiency on-site.

Related Projects

The Keyfix Non-Combustible Cavity Tray System has played an important role in futureproofing a major new residential development in Stratford’s Olympic Park by exceeding new building regulations whilst improving build quality and installation efficiency on site.

Related Projects

The Keyfix Non-Combustible Cavity Tray System has played an essential role in the construction of a new mixed-use development in East London, by exceeding building regulations and increasing installation efficiency on-site.

Related Projects

The Keyfix Non-Combustible Cavity Tray has been installed as part of a major housing project , Park East in South East London, helping to improve efficiency onsite, and to exceed building regulations.

Related Projects

The Keyfix Non-Combustible Cavity Tray System has proven integral to the construction of a new high-rise residential development in South West London, by improving installation efficiency and quality on site, and exceeding building regulations.

Related Projects

Keyfix’s Non-combustible Cavity Tray has provided the effective solution to the government mandate for cavity trays with limited combustibility on a major south east London housing development.

Related Projects

The Keyfix Non-Combustible Cavity Tray System has played a pivotal role in the successful construction of a brand new range of high-end apartments and studios for students at the prestigious University of Nottingham. Photography Credits: McAleer & Rushe

Related Projects

The speed of installation and improved build quality of the Keyfix Non-Combustible Cavity Tray System has played an important part in the construction of a major new high-rise residential development in West London and at the same time help meet and exceed regulatory requirements.

Related Projects

The Keyfix Non-Combustible Cavity Tray has been installed as part of a new residential development in Southend-on-Sea, Essex, offering value for money, ease of construction, and best practice on this project.

Discover our latest CPD “Solving the non-combustible Challenge with Keyfix Cavity Tray systems”

Request CPDEnter your name and email address below to keep up to date with Keyfix product developments, CPDs, industry news and much more.

"*" indicates required fields

Champions of Best Practice

Superior Solutions

Going Above and Beyond

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie records the user consent for the cookies in the "Advertisement" category. |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| rc::a | never | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| rc::c | session | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| __lc_cid | 1 year 1 month 4 days | This is an essential cookie for the website live chat box to function properly. |

| __lc_cst | 1 year 1 month 4 days | This cookie is used for the website live chat box to function properly. |

| __oauth_redirect_detector | 1 minute | This cookie is used to recognize the visitors using live chat at different times inorder to optimize the chat-box functionality. |

| li_gc | 6 months | Linkedin set this cookie for storing visitor's consent regarding using cookies for non-essential purposes. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| yt-remote-cast-installed | session | The yt-remote-cast-installed cookie is used to store the user's video player preferences using embedded YouTube video. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-fast-check-period | session | The yt-remote-fast-check-period cookie is used by YouTube to store the user's video player preferences for embedded YouTube videos. |

| yt-remote-session-app | session | The yt-remote-session-app cookie is used by YouTube to store user preferences and information about the interface of the embedded YouTube video player. |

| yt-remote-session-name | session | The yt-remote-session-name cookie is used by YouTube to store the user's video player preferences using embedded YouTube video. |

| ytidb::LAST_RESULT_ENTRY_KEY | never | The cookie ytidb::LAST_RESULT_ENTRY_KEY is used by YouTube to store the last search result entry that was clicked by the user. This information is used to improve the user experience by providing more relevant search results in the future. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gcl_au | 3 months | Google Tag Manager sets the cookie to experiment advertisement efficiency of websites using their services. |

| _hjSession_* | 1 hour | Hotjar sets this cookie to ensure data from subsequent visits to the same site is attributed to the same user ID, which persists in the Hotjar User ID, which is unique to that site. |

| _hjSessionUser_* | 1 year | Hotjar sets this cookie to ensure data from subsequent visits to the same site is attributed to the same user ID, which persists in the Hotjar User ID, which is unique to that site. |

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 1 year | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser IDs. |

| VISITOR_INFO1_LIVE | 6 months | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| VISITOR_PRIVACY_METADATA | 6 months | YouTube sets this cookie to store the user's cookie consent state for the current domain. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| Cookie | Duration | Description |

|---|---|---|

| __Secure-ROLLOUT_TOKEN | 6 months | Description is currently not available. |